Product Description:

Air-cooled chiller is a kind of chiller equipment, also known as

chiller. It discharges heat by using an air condenser, so it is

called "air-cooled", which is different from the way water-cooled

chillers work, which uses a water condenser to discharge heat.

Compared with the traditional water-cooled chiller, the difference

between the air-cooled chiller and the traditional water-cooled

chiller is that it uses an air cooler as a condenser, and the fan

blows the air required for heat dissipation from one side of the

machine and exhausts it from the other side. Achieve cooling.

Therefore, the air-cooled chiller does not need an external cooling

water source, is independent, and is very convenient to install and

move.

Production Features:

Air-cooled chiller is a common refrigeration equipment, its main

features are as follows:

1.Independence: The air-cooled chiller does not need to be connected to an

external cooling water source through pipes or water pumps. It is

independent and easy to install and move.

2.High efficiency and energy saving: The air-cooled chiller adopts high-efficiency compressors and heat

exchangers, which can reach the set temperature requirements in a

short period of time, and can also reduce energy consumption and

have better energy-saving effects.

3.Easy maintenance: The air-cooled chiller is simple in structure, easy to maintain,

easy to clean and repair.

4.Low noise: The air-cooled chiller has low operating noise and will not

interfere with the surrounding environment and personnel. It is

suitable for places that require a quiet environment.

5.Automatic control: The air-cooled chiller adopts an advanced control system, which

can automatically adjust the temperature and humidity to ensure

stable and reliable cooling effect.

6.Flexibility: The air-cooled chiller can be used alone or in conjunction with

other equipment to meet different needs.

In general, the air-cooled chiller has the characteristics of

independence, high efficiency and energy saving, easy maintenance,

low noise, automatic control and flexibility, and is an ideal

equipment widely used in various refrigeration needs.

Working Principle:

The main components of an air-cooled chiller include a compressor,

an air condenser, an expansion valve, and an evaporator. Here is a

basic overview of its workflow:

1.The compressor takes in low-pressure, low-temperature refrigerant

gas and compresses it into high-pressure, high-temperature gas.

2.This high-temperature, high-pressure refrigerant gas enters the

air condenser, exchanges heat with the ambient air, and discharges

heat to the environment, while the refrigerant condenses from a

gaseous state to a liquid state.

3.The high-pressure refrigerant liquid passes through the expansion

valve, the pressure suddenly drops, and it turns into a

low-pressure and low-temperature refrigerant liquid.

4.The low-temperature and low-pressure refrigerant liquid enters

the evaporator, absorbs indoor heat, evaporates into a gaseous

state by itself, and the indoor temperature drops to achieve the

purpose of refrigeration.

5.The refrigerant gas is sucked into the compressor again to

complete a cycle.

The advantages of air-cooled chillers include simple installation,

no need for cooling towers and cooling water pumps, and low

maintenance costs. However, its efficiency is lower than that of

water-cooled chillers, especially at high ambient temperatures, and

its efficiency will be further reduced

| ① Compressor | ⑤ Evaporator | ⑨ Temperature sensor | ⑬ Bypass valve |

| ② Condenser | ⑥ Ball valve | ⑩ Water tank | ⑭ Low voltage controller |

| ③ Filter drier | ⑦ Antifreeze switch | ⑪ Water pump pressure gauge | ⑮ High voltage controller |

| ④ Expansion valve | ⑧ Float switch | ⑫ Water pump | ⑯ Pressure relief valve |

Techinical Parameters:

| Model | JLSF-1HP | JLSF-2HP | JLSF-3HP | JLSF-4HP | JLSF-5HP | JLSF-6HP | JLSF-8HP | JLSF-10HP |

| Cooling capacity | KW/h | 3.1 | 6.2 | 9.3 | 12.4 | 15.5 | 18.6 | 24.8 | 31 |

| Kcal/h | 2,700 | 5,400 | 8,100 | 10,800 | 13,500 | 16,200 | 21,600 | 27,000 |

| Temperature range | 5℃-35℃(Below 0℃ can be customized) |

| Power supply | 1PH-220V 50HZ/60HZ 3PH-380V/415V 50HZ/60HZ |

| Total power | KW | 1.21 | 2.03 | 2.84 | 3.7 | 4.5 | 5.7 | 7.33 | 8.83 |

| Compressor | Type | | Hermetic scroll type or piston |

| Power | KW | 0.75 | 1.50 | 2.25 | 3.00 | 3.75 | 4.50 | 6.00 | 7.50 |

| Circulating pump | Power | KW | 0.375 | 0.375 | 0.375 | 0.375 | 0.75 | 0.75 | 0.75 | 1.5 |

| Head | m | 22 | 22 | 22 | 22 | 23 | 23 | 23 | 21.5 |

| Refrigerant | Type | | R22/R407c/R134a/R410a |

| Control method | | Temperature Sensing External Pressure Equalizing Expansion Valve |

| filling volume | Kg | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 | 4.00 | 5.00 |

| Evaporator | Flow | m³/h | 0.82 | 0.98 | 1.45 | 1.88 | 2.42 | 2.92 | 3.75 | 4.85 |

| water capacity | m³ | 0.028 | 0.04 | 0.05 | 0.05 | 0.065 | 0.065 | 0.13 | 0.18 |

| Diameter | inch | 1/2" | 3/4" | 1" | 1-1/2" | 1-1/2" |

| Condensator | Type | Efficient brass sets corrugated aluminum fin |

| Fan | Type | Axial flow |

| air volume | m³/h | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Protective device | High and low pressure switch, antifreeze protection, fusible

plug/safety valve, overload protection device, coil overheat

protector, automatic temperature protection switch, etc. |

| Machine size | L | mm | 680 | 800 | 1040 | 1140 | 1140 | 1200 | 1400 | 1400 |

| W | mm | 420 | 480 | 555 | 620 | 620 | 650 | 725 | 725 |

| H | mm | 720 | 850 | 1060 | 1200 | 1200 | 1160 | 1450 | 1450 |

| Unit weight | Kg | 60 | 90 | 130 | 140 | 170 | 210 | 270 | 350 |

| Model | JLSF-12HP | JLSF-15HP | JLSF-20HP | JLSF-25HP | JLSF-30HP | JLSF-40HP | JLSF-50HP | JLSF-60HP |

| Cooling capacity | KW/h | 37.2 | 46.5 | 65 | 77.5 | 93 | 124 | 155 | 186 |

| Kcal/h | 29,059 | 37,965 | 50,805 | 61,683 | 74,992 | 97,675 | 116,521 | 156,249 |

| Temperature range | 5℃-35℃(Below 0℃ can be customized) |

| Power supply | 1N-220V 50HZ/60HZ 3N-380V/415V 50HZ/60HZ |

| Total power | KW | 11.4 | 13.62 | 19.8 | 22.75 | 28.3 | 39.2 | 46.75 | 56.1 |

| Compressor | Type | | Hermetic scroll type or piston |

| Power | KW | 9 | 11.25 | 15 | 18.75 | 22.5 | 30 | 37.5 | 45 |

| Circulating pump | Power | KW | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 4 | 5.5 |

| Head | m | 21.5 | 21.5 | 22 | 22 | 25 | 25 | 25 | 26 |

| Refrigerant | Type | | R22/R407c/R134a/R410a |

| Control method | | Temperature Sensing External Pressure Equalizing Expansion Valve |

| filling volume | Kg | 7.2 | 9.1 | 12.2 | 15.3 | 18.6 | 24.5 | 30.6 | 36.8 |

| Evaporator | Flow | m³/h | 5.81 | 7.6 | 10.16 | 12.34 | 15.2 | 19.53 | 23.3 | 30.52 |

| water capacity | m³/h | 0.18 | 0.21 | 0.28 | 0.32 | 0.32 | 0.61 | 0.66 | 0.72 |

| Diameter | inch | 1.5" | 2" | 2.5" | 3" |

| Condensator | Type | | Efficient brass sets corrugated aluminum fin |

| Fan | Type | | Axial flow |

| air volume | m³/h | 12000 | 15000 | 20000 | 25000 | 30000 | 40000 | 50000 | 60000 |

| Protective device | High and low pressure switch, antifreeze protection, fusible

plug/safety valve, overload protection device, coil overheat

protector, automatic temperature protection switch, etc. |

| Machine size | L | mm | 1400 | 1750 | 2000 | 2000 | 2200 | 2000 | 2000 | 2400 |

| W | mm | 725 | 750 | 900 | 900 | 900 | 1800 | 1800 | 1800 |

| H | mm | 1450 | 1500 | 1770 | 1770 | 1770 | 2200 | 2300 | 2300 |

| Unit weight | Kg | 370 | 480 | 590 | 590 | 880 | 1000 | 1280 | 1420 |

Application Industry:

Small air-cooled chillers are suitable for many different

industries and applications, including but not limited to the

following:

1.Electronics industry: Small air-cooled chillers can provide refrigeration for high-tech

products such as semiconductors, optics, and electronic components

to ensure the normal operation of the equipment.

2.Pharmaceutical industry: small air-cooled chillers can provide stable cooling effect for

the link in the pharmaceutical production process that requires

temperature control, ensuring the quality and safety of

pharmaceuticals.

3.Food industry: Small air-cooled chillers can provide refrigeration for the links

that require temperature control during food processing, storage

and transportation to ensure the quality and safety of food.

4.Plastic industry: small air-cooled chillers can provide refrigeration for the

temperature-controlled links in plastic injection molding, blow

molding, extrusion molding, etc., to ensure product quality and

production efficiency.

5.Chemical industry: small air-cooled chillers can provide refrigeration for the links

that need temperature control in the chemical production process to

ensure the quality and safety of chemical products.

In general, small air-cooled chillers are suitable for various

occasions that require refrigeration, and provide efficient, stable

and reliable refrigeration solutions for different industries.

Automotive Manufacturing Chemical Engineering Electronics Industry

Electroplating Industry

Injection Molding Industry Pharmaceutical Industry Plastic

Packaging Industry Printing Industry

Upport and Services:

Air Cooled Chiller technical support and service includes:

1. 24/7 customer support

2. Remote guidance installation and maintenance

3. Remote Diagnostics and Troubleshooting

4. Phone/Email Advice and Guidance

5. User friendly documentation and manuals

6. Software Updates and Upgrades

7. Cost price of spare parts and consumables

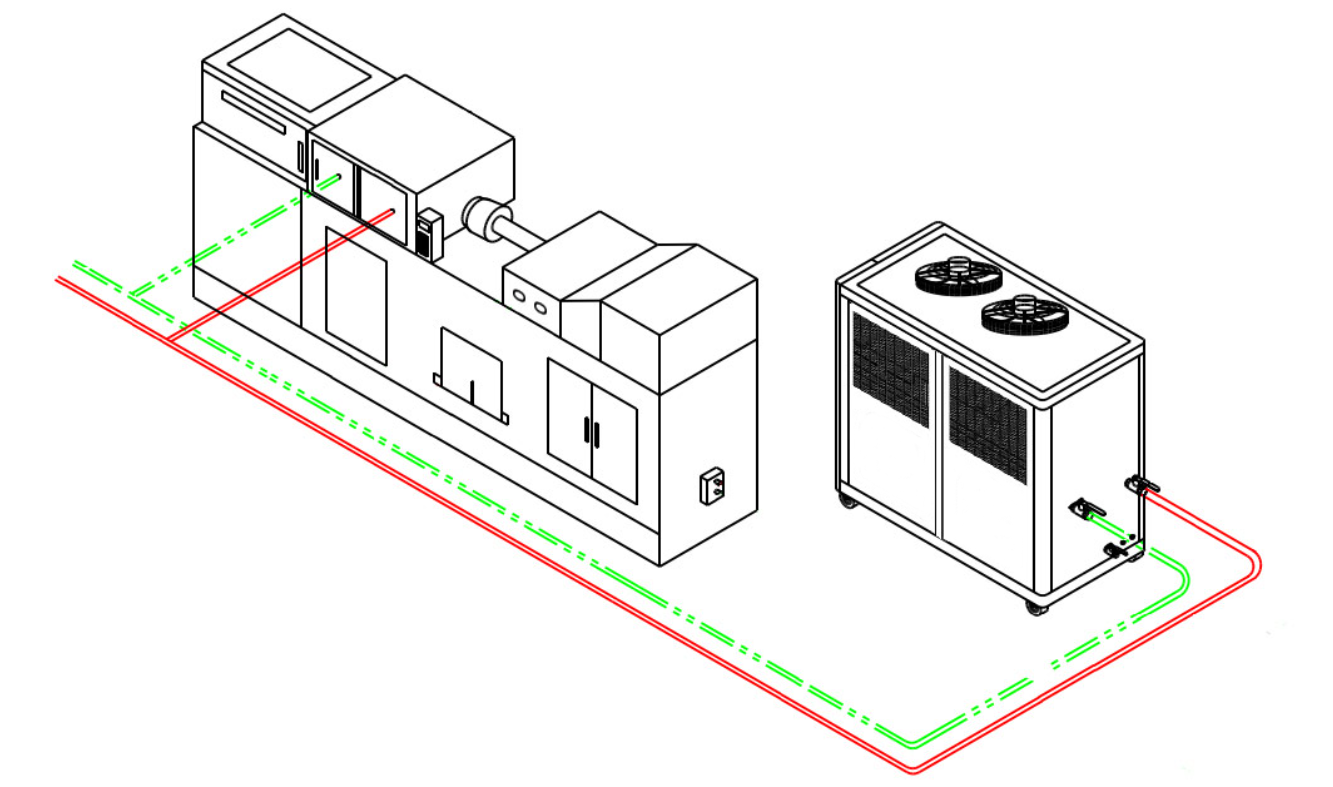

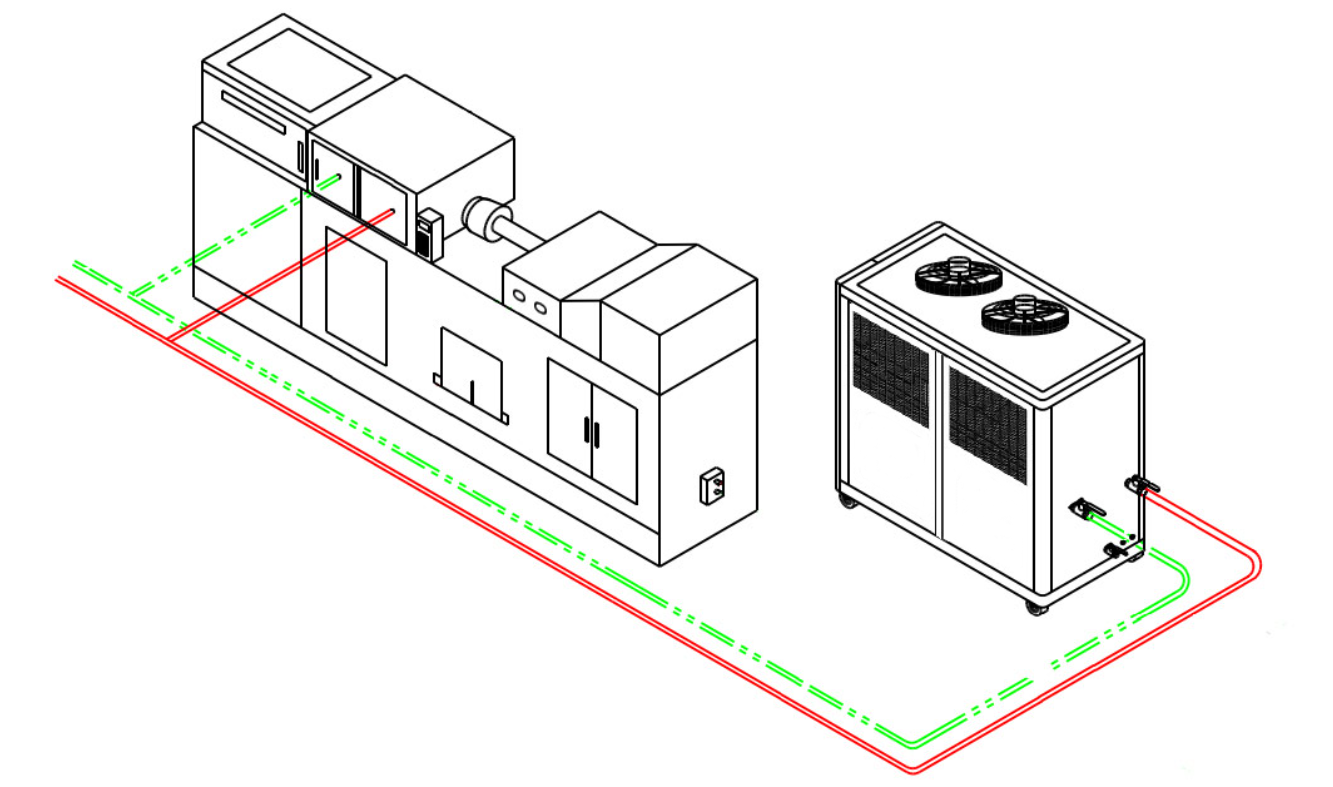

Application of Chiller in Extruder:

The application of water chillers in extruders is mainly used to

cool the heating elements of the extruder and the heat generated

during the extrusion process to ensure the stability and quality of

the extrusion process.

During the working process of the extruder, materials such as

plastics or rubber are extruded into products of specific shapes,

such as pipes, cables, films, etc., through heating and pressure.

In this process, the extruder needs to perform constant temperature

control on the heating elements (such as heating barrels) to

maintain the required extrusion temperature.

The water chiller reduces the temperature of the extruder by

circulating cooling water. It passes the cooling water through the

cooling system and then connects the cooling water to the heating

elements in the extruder through pipes or cooling loops. The

cooling water absorbs the heat released by the heating elements and

takes it away, thereby maintaining a stable temperature during the

extrusion process.

The application of water chillers can bring the following benefits:

1. Temperature control: The water chiller can provide precise cooling effect to ensure

that the temperature of the heating elements in the extruder

remains within the required range, avoiding the impact of

overheating or overcooling on the extrusion process and product

quality.

2. Stability: By cooling the extruder, the water chiller can help maintain the

stability of the extrusion process and reduce the impact of

temperature fluctuations on product size, appearance and

performance.

3. Improve production efficiency: The chiller can quickly cool the heating element, reduce the time

of the extruder during startup and shutdown, and improve production

efficiency and output.

4. Extend equipment life: By controlling the temperature of the extruder, the chiller can

reduce the damage to the equipment caused by thermal stress, and

extend the service life and reliability of the equipment.

In short, the application of the chiller in the extruder can

provide precise temperature control, ensure the stability of the

extrusion process and product quality, and improve production

efficiency and equipment life.