JLSF-75HP Air Cooled Water Chiller Using Denmark Danfoss Scroll

Compressor

Product Description:

Air-cooled scroll chiller is a device used in refrigeration and

air-conditioning systems that uses air-cooled condenser and scroll

compressor technology.

Air-cooled scroll chillers utilize an air-cooled condenser to

dissipate heat. The condenser is an important component in the

refrigeration cycle. It cools and converts high-temperature and

high-pressure refrigerant gas into high-pressure liquid.

Traditional chillers usually use a water-cooled condenser to

dissipate heat and need to be connected to a cooling tower or other

water source for cooling. The air-cooled scroll chiller uses a fan

to blow across the fins on the condenser surface to take away the

heat and achieve heat dissipation.

Air-cooled scroll chillers have several advantages over traditional

water-cooled chillers. First, it does not need to be connected to

an external water source, making installation more convenient.

Secondly, since there are no additional equipment such as water

pumps and cooling towers, the system is simpler and takes up less

space. In addition, air-cooled scroll chillers usually have a high

energy efficiency ratio and can provide stable cooling effects.

Product Features:

Air-cooled scroll chiller is a special type of chiller with the

following characteristics:

1. Efficient cooling capacity: The air-cooled scroll chiller uses a scroll compressor and has

efficient cooling capacity. It can provide powerful cooling

capacity and is suitable for large or high-load cooling needs.

2. Independent cooling system: The air-cooled scroll chiller uses an independent air-cooling

system to dissipate heat to the surrounding environment through

fans. Compared with traditional water-cooled chillers, it does not

require additional cooling water sources or cooling towers, making

it more convenient and space-saving.

3. Automatic control and adjustment: Air-cooled scroll chillers are usually equipped with advanced

automatic control systems that can monitor and adjust the operating

status of the cooling system. It can automatically start and stop

according to actual needs, and perform precise temperature control

according to the set temperature range.

4. Energy saving and environmental protection: Due to the use of an independent air cooling system, air-cooled

scroll chillers have lower energy consumption than water-cooled

chillers. It does not require water pump operation and water

circulation, reducing energy consumption and water use. At the same

time, since there is no need for a cooling tower, water treatment

and chemical use are reduced, making it more environmentally

friendly.

5. Flexible installation and mobility: Air-cooled scroll chillers usually have a compact design and

wheeled base for easy installation and movement. They can be

flexibly arranged and adjusted as needed and are suitable for a

variety of locations and applications, including industrial

production, commercial buildings and temporary cooling of events.

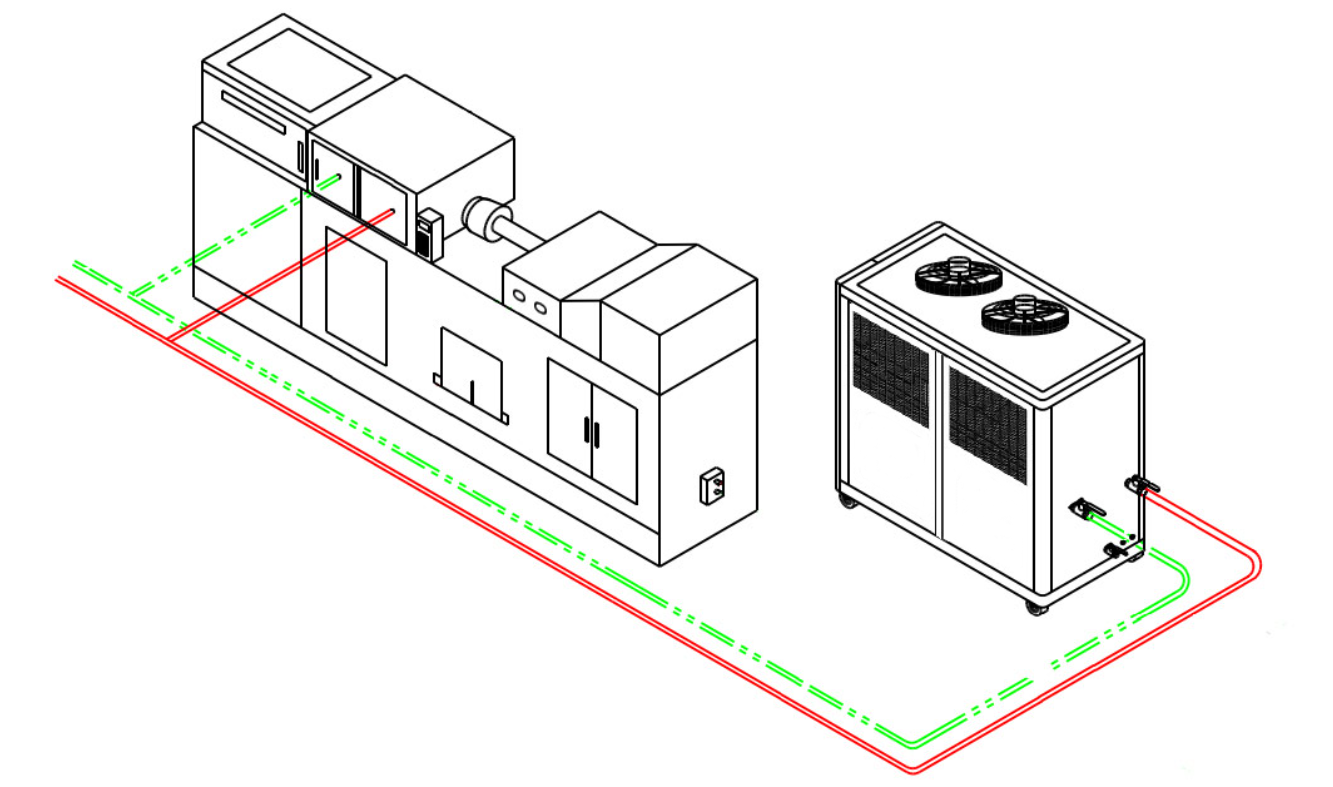

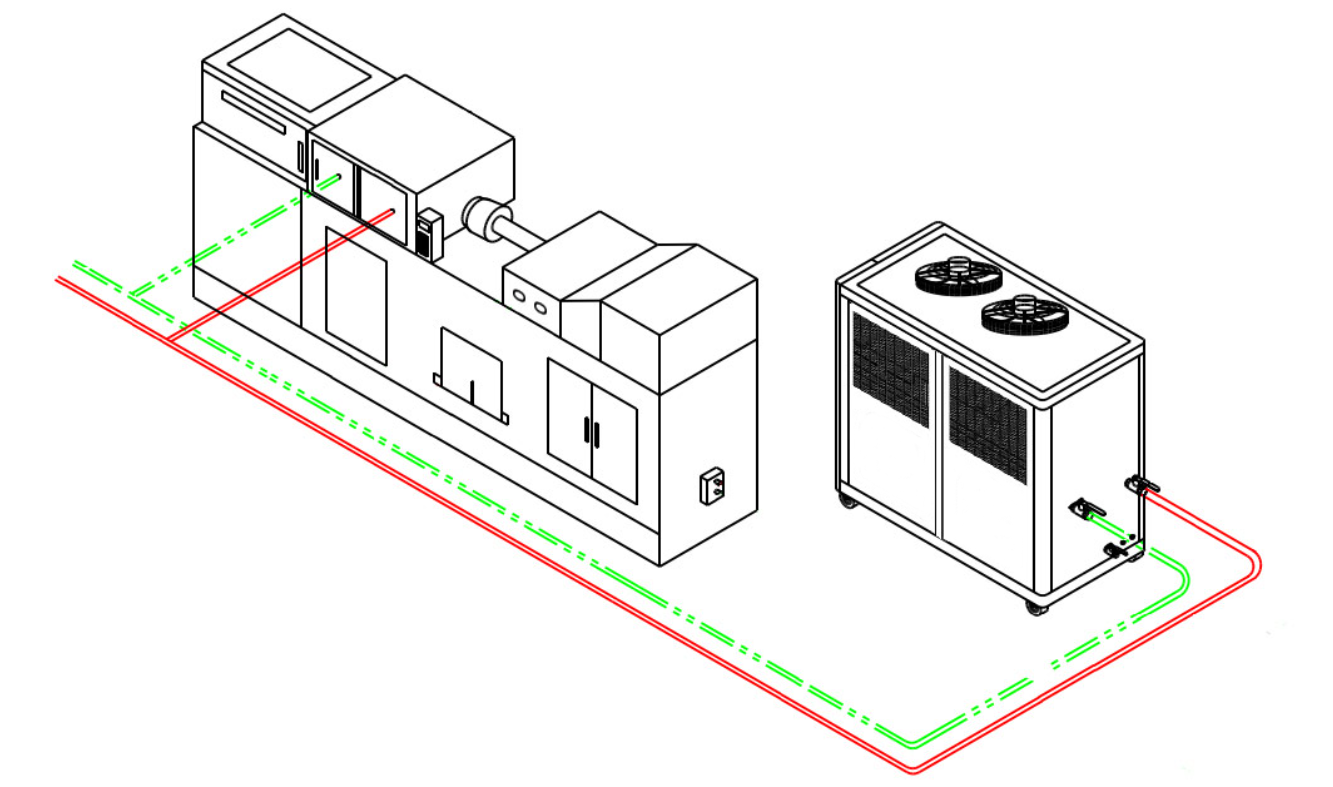

Working Principle:

The working principle of the air-cooled scroll chiller can be

divided into two main parts: refrigeration cycle and heat

dissipation cycle.

Refrigeration cycle part:

1. Compression: The core of the refrigeration cycle is the scroll compressor. The

compressor sucks in low-temperature and low-pressure refrigerant

gas, and then increases its pressure and temperature through

rotation and compression.

2. Condensation: The compressed high-temperature and high-pressure refrigerant gas

enters the air-cooled condenser. In the condenser, a cooling fan

blows outdoor air over the condenser's fins, causing the

refrigerant gas to dissipate heat and cool down. When the

refrigerant gas is cooled, it turns into a high-pressure liquid.

3. Expansion: High-pressure liquid refrigerant enters the evaporator through the

expansion valve (throttle device). The function of the expansion

valve is to reduce the pressure of the refrigerant, causing it to

expand rapidly, thereby reducing the temperature and pressure.

Heat dissipation cycle part:

1. Evaporation: The expanded low-temperature and low-pressure refrigerant enters

the evaporator. A finned tube or radiator is installed inside the

evaporator. By contacting the water or air to be cooled, it absorbs

heat and cools the water or air.

2. Cold water supply: The water cooled in the evaporator is sent to the equipment or

system that needs to be cooled to absorb heat and reduce the

temperature.

3. Cooling cycle: The cold water is transported back to the equipment or system to

be cooled through the circulation pump and circulated for cooling,

forming a closed-loop cycle.

During the entire process, the refrigerant completes the cycle of

compression, condensation, expansion and evaporation under the

action of the compressor, absorbing and releasing heat, thereby

achieving the refrigeration effect of cold water. The air-cooled

condenser removes heat through a fan to ensure that the refrigerant

can continue to cool and circulate during the cycle.

| ① Compressor | ⑤ Evaporator | ⑨ Temperature sensor | ⑬ Bypass valve |

| ② Condenser | ⑥ Ball valve | ⑩ Water tank | ⑭ Low voltage controller |

| ③ Filter drier | ⑦ Antifreeze switch | ⑪ Water pump pressure gauge | ⑮ High voltage controller |

| ④ Expansion valve | ⑧ Float switch | ⑫ Water pump | ⑯ Pressure relief valve |

Techinical Parameters:

| Model | JLSF-1HP | JLSF-2HP | JLSF-3HP | JLSF-4HP | JLSF-5HP | JLSF-6HP | JLSF-8HP | JLSF-10HP |

| Cooling capacity | KW/h | 3.1 | 6.2 | 9.3 | 12.4 | 15.5 | 18.6 | 24.8 | 31 |

| Kcal/h | 2,700 | 5,400 | 8,100 | 10,800 | 13,500 | 16,200 | 21,600 | 27,000 |

| Temperature range | 5℃-35℃(Below 0℃ can be customized) |

| Power supply | 1PH-220V 50HZ/60HZ 3PH-380V/415V 50HZ/60HZ |

| Total power | KW | 1.21 | 2.03 | 2.84 | 3.7 | 4.5 | 5.7 | 7.33 | 8.83 |

| Compressor | Type | | Hermetic scroll type or piston |

| Power | KW | 0.75 | 1.50 | 2.25 | 3.00 | 3.75 | 4.50 | 6.00 | 7.50 |

| Circulating pump | Power | KW | 0.375 | 0.375 | 0.375 | 0.375 | 0.75 | 0.75 | 0.75 | 1.5 |

| Head | m | 22 | 22 | 22 | 22 | 23 | 23 | 23 | 21.5 |

| Refrigerant | Type | | R22/R407c/R134a/R410a |

| Control method | | Temperature Sensing External Pressure Equalizing Expansion Valve |

| filling volume | Kg | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 | 4.00 | 5.00 |

| Evaporator | Flow | m³/h | 0.82 | 0.98 | 1.45 | 1.88 | 2.42 | 2.92 | 3.75 | 4.85 |

| water capacity | m³ | 0.028 | 0.04 | 0.05 | 0.05 | 0.065 | 0.065 | 0.13 | 0.18 |

| Diameter | inch | 1/2" | 3/4" | 1" | 1-1/2" | 1-1/2" |

| Condensator | Type | Efficient brass sets corrugated aluminum fin |

| Fan | Type | Axial flow |

| air volume | m³/h | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Protective device | High and low pressure switch, antifreeze protection, fusible

plug/safety valve, overload protection device, coil overheat

protector, automatic temperature protection switch, etc. |

| Machine size | L | mm | 680 | 800 | 1040 | 1140 | 1140 | 1200 | 1400 | 1400 |

| W | mm | 420 | 480 | 555 | 620 | 620 | 650 | 725 | 725 |

| H | mm | 720 | 850 | 1060 | 1200 | 1200 | 1160 | 1450 | 1450 |

| Unit weight | Kg | 60 | 90 | 130 | 140 | 170 | 210 | 270 | 350 |

| Model | JLSF-12HP | JLSF-15HP | JLSF-20HP | JLSF-25HP | JLSF-30HP | JLSF-40HP | JLSF-50HP | JLSF-60HP |

| Cooling capacity | KW/h | 37.2 | 46.5 | 65 | 77.5 | 93 | 124 | 155 | 186 |

| Kcal/h | 29,059 | 37,965 | 50,805 | 61,683 | 74,992 | 97,675 | 116,521 | 156,249 |

| Temperature range | 5℃-35℃(Below 0℃ can be customized) |

| Power supply | 1N-220V 50HZ/60HZ 3N-380V/415V 50HZ/60HZ |

| Total power | KW | 11.4 | 13.62 | 19.8 | 22.75 | 28.3 | 39.2 | 46.75 | 56.1 |

| Compressor | Type | | Hermetic scroll type or piston |

| Power | KW | 9 | 11.25 | 15 | 18.75 | 22.5 | 30 | 37.5 | 45 |

| Circulating pump | Power | KW | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 4 | 5.5 |

| Head | m | 21.5 | 21.5 | 22 | 22 | 25 | 25 | 25 | 26 |

| Refrigerant | Type | | R22/R407c/R134a/R410a |

| Control method | | Temperature Sensing External Pressure Equalizing Expansion Valve |

| filling volume | Kg | 7.2 | 9.1 | 12.2 | 15.3 | 18.6 | 24.5 | 30.6 | 36.8 |

| Evaporator | Flow | m³/h | 5.81 | 7.6 | 10.16 | 12.34 | 15.2 | 19.53 | 23.3 | 30.52 |

| water capacity | m³/h | 0.18 | 0.21 | 0.28 | 0.32 | 0.32 | 0.61 | 0.66 | 0.72 |

| Diameter | inch | 1.5" | 2" | 2.5" | 3" |

| Condensator | Type | | Efficient brass sets corrugated aluminum fin |

| Fan | Type | | Axial flow |

| air volume | m³/h | 12000 | 15000 | 20000 | 25000 | 30000 | 40000 | 50000 | 60000 |

| Protective device | High and low pressure switch, antifreeze protection, fusible

plug/safety valve, overload protection device, coil overheat

protector, automatic temperature protection switch, etc. |

| Machine size | L | mm | 1400 | 1750 | 2000 | 2000 | 2200 | 2000 | 2000 | 2400 |

| W | mm | 725 | 750 | 900 | 900 | 900 | 1800 | 1800 | 1800 |

| H | mm | 1450 | 1500 | 1770 | 1770 | 1770 | 2200 | 2300 | 2300 |

| Unit weight | Kg | 370 | 480 | 590 | 590 | 880 | 1000 | 1280 | 1420 |

Application Industry:

Small air-cooled chillers are suitable for many different

industries and applications, including but not limited to the

following:

1.Electronics industry: Small air-cooled chillers can provide refrigeration for high-tech

products such as semiconductors, optics, and electronic components

to ensure the normal operation of the equipment.

2.Pharmaceutical industry: small air-cooled chillers can provide stable cooling effect for

the link in the pharmaceutical production process that requires

temperature control, ensuring the quality and safety of

pharmaceuticals.

3.Food industry: Small air-cooled chillers can provide refrigeration for the links

that require temperature control during food processing, storage

and transportation to ensure the quality and safety of food.

4.Plastic industry: small air-cooled chillers can provide refrigeration for the

temperature-controlled links in plastic injection molding, blow

molding, extrusion molding, etc., to ensure product quality and

production efficiency.

5.Chemical industry: small air-cooled chillers can provide refrigeration for the links

that need temperature control in the chemical production process to

ensure the quality and safety of chemical products.

In general, small air-cooled chillers are suitable for various

occasions that require refrigeration, and provide efficient, stable

and reliable refrigeration solutions for different industries.

Automotive Manufacturing Chemical Engineering Electronics Industry

Electroplating Industry

Injection Molding Industry Pharmaceutical Industry Plastic

Packaging Industry Printing Industry

Upport and Services:

Chiller technical support and service includes:

1. 24/7 customer support

2. Remote guidance installation and maintenance

3. Remote Diagnostics and Troubleshooting

4. Phone/Email Advice and Guidance

5. User friendly documentation and manuals

6. Software Updates and Upgrades

7. Cost price of spare parts and consumables

Packing and Shipping:

Chillers are packaged and shipped in standard plywood wooden boxes.

All components are secured and protected with a film, and the unit

is then placed on a pallet for easy transport. And affix the

shipping mark information label on the wooden box to ensure correct

delivery.

Precautions for using chiller?

When using a water chiller, you need to pay attention to the

following matters:

1. Safe operation: Be familiar with and follow the operation manual and safe

operating procedures of the chiller. Ensure that operators have the

necessary training and skills and understand the operating

principles and safety precautions of the equipment.

2. Electrical safety: Ensure that the electrical connections of the chiller comply with

electrical standards and requirements. Avoid overloading electrical

outlets and make sure power lines are reliable and checked

regularly.

3. Water quality management: If the chiller uses a water cooling system, pay attention to water

quality management and maintenance. Check water quality regularly

and clean or replace filters in your water cooling system to avoid

the build-up of scale and dirt.

4. Temperature control: Set and monitor the temperature control parameters of the chiller

as needed. Ensure that the set temperature range meets application

requirements and adjust temperature control promptly to meet needs.

5. Maintenance: Perform regular maintenance on the chiller, including cleaning the

condenser, checking the accuracy of the pressure sensor and

temperature sensor, and lubricating moving parts. Follow the

maintenance guidelines and schedule provided by the manufacturer.

6. Troubleshooting: If the chiller fails or is abnormal, first check whether the power

supply and electrical connections are normal. If the problem

persists, you should contact professional maintenance personnel for

troubleshooting and repair, and avoid repair or operation by

yourself.

7. Environmental requirements: When installing the chiller, ensure that the surrounding

environment is well ventilated and avoid blocking the cooling fan

or air inlet and outlet. Avoid using the chiller in an environment

with harmful gases or corrosive substances.

8. Temperature changes: The temperature may change when the chiller is started or stopped.

Before starting, make sure the system is at the proper temperature.

After a stop, avoid shutting down the chiller suddenly, but instead

gradually reduce the load and allow the system to cool for a period

of time.

9. Cleaning and protection: Clean the casing and internal parts of the chiller regularly to

ensure that the radiator and fan are free of dust and blockage. Use

appropriate protective measures to protect the chiller from harsh

environmental conditions.

10. Recycling and disposal: Properly dispose of waste refrigerant and other chiller-related

waste in accordance with local environmental regulations and

regulations.

These usage precautions can help ensure safe operation and

performance of your chiller while extending the life of the

equipment. It is important to follow the usage guidelines and

recommendations provided by the manufacturer and perform

appropriate operation and maintenance based on actual conditions.